Pressure turning green creates diamonds for the world

Green transition trend - Pressure from the global government

In the context where legislators in Europe and developed countries have taken bold steps, exemplified by the EU CBAM, a mechanism that imposes carbon tariffs on imported goods, putting pressure on external suppliers to transition to green, balancing carbon costs between supply sources and eliminating "carbon leakage." The emergence of the EU CBAM, from its planning stages to its approval and initial implementation, has sparked interest and waves of public opinion worldwide. The mechanism has motivated many countries to enact stricter environmental policies, such as Japan's fossil fuel import tax and UK CBAM, building a carbon credit market ETS preparing to operate in countries like Australia, Austria, and Brazil.

Developing regions in Southeast Asia, such as Vietnam, may also face potential negative impacts from CBAM. Industries like steel, aluminum, and cement, which are key export sectors of these countries, may be significantly affected. For instance, Vietnam's steel exports to the EU could decrease by 3.7% due to additional costs imposed by CBAM. Expanding the scope of CBAM to include the plastic industry could further exacerbate negative impacts on Southeast Asian economies.

According to Ms. Luu Thi Mai Huong - Certification Director of Bureau Veritas, who shared with VTV: "For demanding markets like the United States, they have high environmental protection requirements that their suppliers must meet. However, it is encouraging that Vietnamese businesses are now proactively implementing these sustainable standards because it is a trend." Understanding global trends in carbon neutrality along with the roadmap that Vietnam has developed and is implementing is essential. To raise awareness and drive transformation, this article will provide potential solutions and recommend a roadmap to reduce emissions, contributing to the global goal of carbon neutrality.

Vietnam's carbon neutrality roadmap - Notes for businesses

Following commitments made at COP 26, the Vietnamese government has taken practical steps and outlined the nation's net-zero roadmap. Understanding government decrees and regulations is essential for businesses in their business planning and green transition. The following notes in legal documents will somewhat help businesses better understand the regulations and, above all, get closer to their own goals.

Greenhouse gas inventory:

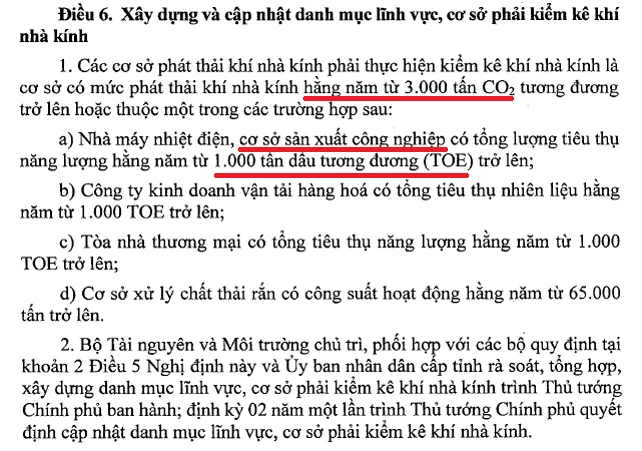

The state has mandated that energy-intensive facilities must inventory carbon emissions since 2020 and update, expand this inventory by early 2022. There are around 3000 facilities, businesses in this inventory who must conduct emissions inventories every 3 years to build a data system, aiding the government in tracking emissions to make appropriate roadmap adjustments and regulations.

National roadmap:

Even though the goals and indicators may be adjusted in the future, the government has set emission limits and mandatory reduction levels for certain industries and sectors. These goals help businesses see the involvement of the government machinery as well as the alignment of the people in protecting the environment. Facilities and businesses with large emissions can rely on this information to plan long-term for themselves.

Technical guidance on measurement, reporting of emission reductions, and inventory:

The Ministry of Natural Resources and Environment has issued a decree for waste management facilities. This decree is considered the first official guidance from the state and can apply a reporting and measurement framework for other industries and sectors.

Greenhouse gas inventory - Foundation for action:

Before embarking on the journey towards carbon neutrality, businesses in the industry need to understand their greenhouse gas emissions. Conducting an emission inventory is an important step to assess the current impact of these businesses on the environment. By identifying and categorizing emissions from various sources in production activities, businesses can determine areas that need improvement and set feasible emission reduction targets.

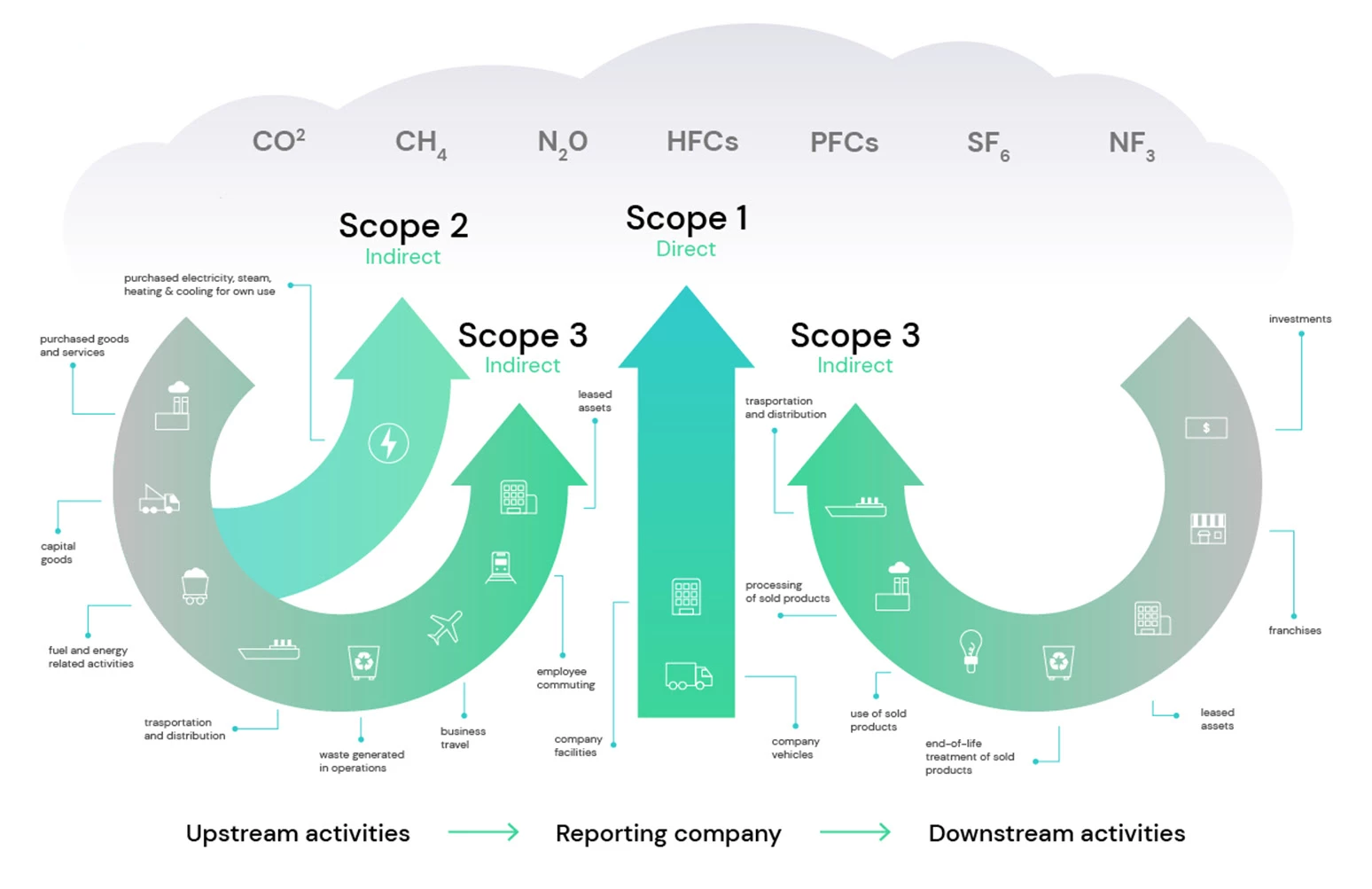

To effectively monitor emission data, it is necessary to understand the concept of scope division. The Greenhouse Gas (GHG) emission framework classifies emissions into three scopes:

Scope 1: Direct emissions from sources owned or controlled by the company, such as fuel combustion in production processes or company-owned vehicles. (According to current regulations in Vietnam - all assets owned by the company fall under scope 1).

Scope 2: Indirect emissions from electricity, heat, or steam purchased by the company.

Scope 3: Indirect emissions occurring in the company's value chain, including activities such as procurement, transportation, and waste management.

Effective communication ensures accurate data transfer between departments, allowing for an overall view of the company's emissions. This process involves collecting data from various sources, including energy consumption records, transportation logs, and waste management reports. This collaboration is essential to identify emission hotspots and implement targeted mitigation strategies.

Challenges in cost, emission reduction methods

Standardizing the greenhouse gas inventory process allows companies to identify primary emission sources. Most greenhouse gas emissions from industrial sectors are carbon dioxide emissions (CO2), with four main industrial sectors—plastics, cement, chemicals, and steel—contributing significantly. Reducing CO2 emissions from these sectors poses several technical challenges.

Firstly, about 45% of CO2 emissions in these sectors originate from input materials, which cannot be reduced by changing fuels but require process modifications. Secondly, around 35% of emissions come from burning fossil fuels to generate high heat, making it difficult to switch to alternative fuels. The high integration of industrial processes (the third challenge) requires changes in many components, making emission reduction complex. Finally, existing production facilities have long lifespans and require costly repairs or upgrades to implement emission reduction processes.

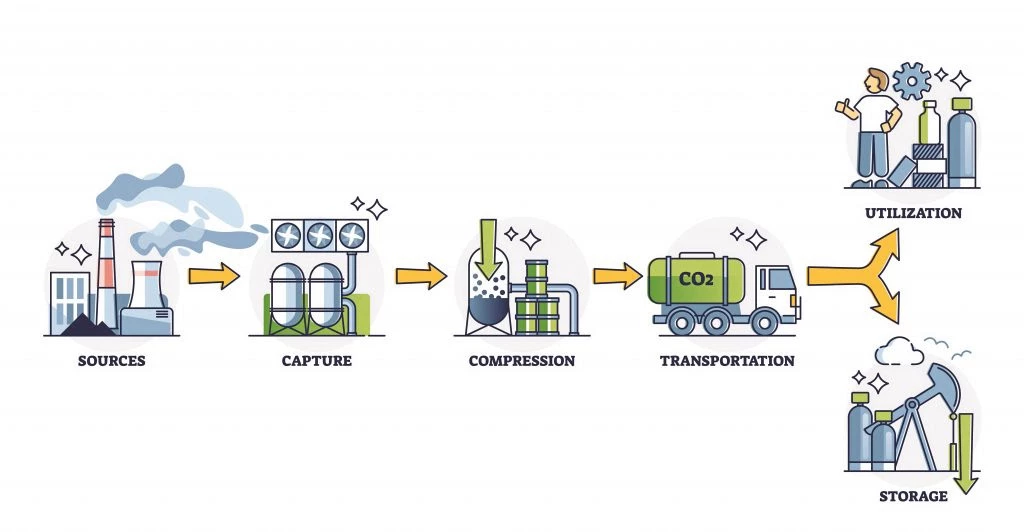

The steps in the roadmap from inventory to emission reduction implementation bring many benefits to businesses. The collected data can be used to consider trading carbon credits to offset carbon emissions into the environment. Typically, each credit is equivalent to 1 ton of carbon (CO2e) emissions. The price of each credit depends on the project quality, with reforestation projects usually having the highest value followed by renewable energy and carbon capture and storage (CCS) projects. Using credits may be the most cost-effective option in some production types with difficult process changes.