The reality of carbon emissions and recommendation for the manufacturing industry

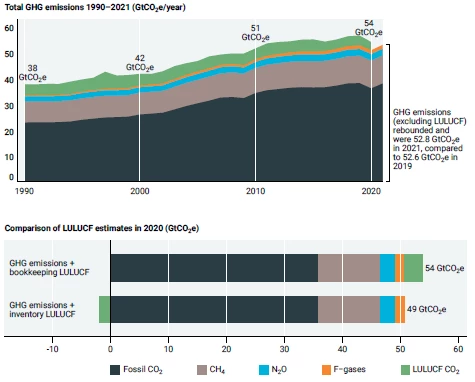

Since 1990, almost every year, the world reached a new record for Greenhouse gas (GHG) emissions. Between 2010 and 2019, average yearly growth was 1.1 percent, compared to 2.6 percent between 2000 and 2009. Even though there is a decadal slowdown in emissions, global GHG emissions for 2022 are about 58 gigatons of CO2 equivalent (GtCO2e), The largest annual level ever recorded. As the carbon emissions level grew yearly, global warming was estimated to be 3.2 degrees Celsius in 2100, leading to droughts, storms and rising sea levels at a warning rate, many well-known cities will become unlivable because of pollution and harsh condition. In 2017, the cost of reducing the impact of climate change around the world is USD 320 billion. Floods and drought have brought starvation and poverty as they affect food supplies. According to Power Plant’s report, 4.2 million fatalities because of air pollution per year. If this scenario keeps happening, 142 million people will become migrants in 2050. The UN and many countries that agree with United Nations Framework Convention on Climate Change (UNFCCC) plan to keep global warming at 1.5 degrees Celsius.

Both compliance and voluntary methods have been adopted and implemented by governments worldwide. Governments created the market for carbon credits and offsets, a new way to positively impact the environment. Carbon taxes are also a useful tool for governors to target large emitters, the EU’s Carbon Border Adjustment Mechanism (CBAM) first applies to imports of specified items and selected precursors whose manufacturing is carbon intensive and poses the greatest danger of carbon leakage: cement, iron and steel, aluminum, fertilizers, power, and hydrogen. On the other hand, in other countries like the United States, carbon taxes aim at factories, manufacturers and heavily emitted supply chains (Stemming Warming and Augmenting Pay Act – SWAP 2019).

Vietnam also agrees to several terms and agreements to reduce GHG emissions, in the UN Climate Change Conference (COP26) November 2021 by the UNFCCC, Vietnam committed to meet net zero carbon emissions in 2050, no more coal electricity in 2040 and stopping deforestation in 2030. Recently on March 4, 2023, Vietnam participated in the conference under the "Asian Zero Emissions Community" (AZEC) in Tokyo, Japan. Vietnam and 11 other Asian countries committed to effectively eliminating emissions without affecting economic development and energy supply. Japan will provide policy advice, technical support, and financial assistance to help Asian countries achieve net-zero emissions more smoothly. According to decision number 01/2020 by the prime minister of Vietnam, there are six industries and nearly 2000 facilities have to provide their GHG emissions level, mostly are factories.

Based on decree number 06/2022, the Vietnam government will open a carbon credits market for emissions-exceeding companies by 2028, allowing companies to buy credits and offsets from overseas suppliers.

The overall picture of manufacturing industry and recommendations for business

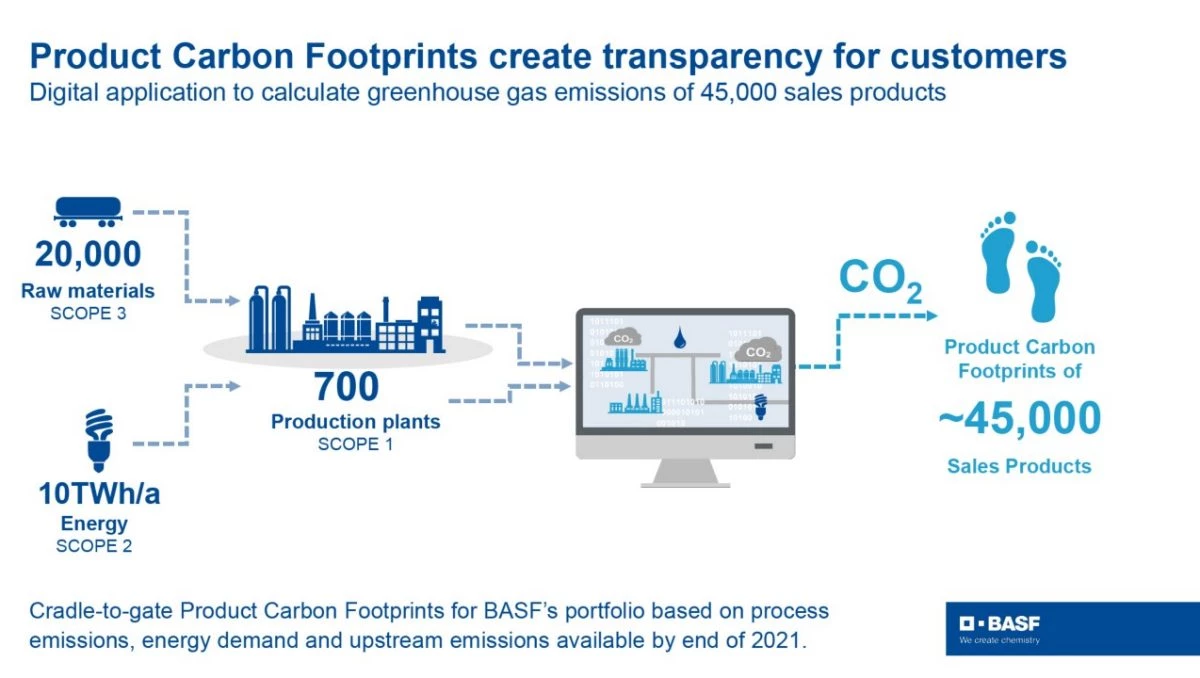

Manufacturing companies are part of large emitters which the government is concerned for. In 2019, the manufacturing industry emitted 6.3 gigatons of CO2, accounting for 12.7% of the global emissions and 22% of Europe's total CO2 emissions, making it the third-largest emitter after energy and transport. With stricter environmental regulations and increasing public pressure, companies are now taking steps to gather product carbon footprint (PCF) data internally from partners and suppliers, these data are then categorized into three scopes as per the Greenhouse gas Protocol.

Collected product carbon footprint (PCF) data helps enable transparency and aggregation database storage, which promotes peer-to-peer seamless data exchange. By analyzing PCF, firms can determine the carbon intensity of the technology and energy used to make a product. This allows them to innovate in energy usage, value chain technologies, and information transmission, which are key characteristics in reducing GHG emissions in manufacturing companies. Businesses need to understand new carbon emission laws and regulations, prepare a data-sharing platform, and budget for new technologies and fuels. However, these efforts take many resources and innovation costs to initiate. Carbon credits and offsets are options for companies that couldn’t decarbonize their value chain.

Mandatory programs that restrict greenhouse gas emissions continue to emerge in Europe and a few states of America, leading to the evolution of a segmented carbon compliance market. In a compliance market, businesses with minimal emissions have the option to sell their surplus allowances to larger emitters. This is a viable option for manufacturing companies facing the high cost of GHG reduction and technology innovation.

Another option for companies and individuals looking to make a positive and immediate impact on the environment is carbon offsets, which reduce or eliminate the carbon footprint directly from the atmosphere. These offsets are provided by environmental firms and are not mandatory. Manufacturing companies should explore all options available to them and take proactive steps to reduce their emissions to minimize environmental impacts for a greener earth.

- To keep up with the trend and comply with the new regulations of the government, manufacturing companies need to update information on carbon credits and carbon taxes in order to understand the information and have a plan to reduce emissions for the supply chain.

- At the same time, methods of collecting, classifying, and analyzing PCF data need to be implemented early by businesses to have a comprehensive picture of emissions.

- From there, companies can innovate their technology in using energy, fuel, and upgrading their own value chains. This is one of the common processes that manufacturing companies have been using recently.